Height Safety Equipment Inspection

Working at heights and falls is currently one of the largest contributors to injuries and worse in the Australian workplace. In 2021, national data indicated 19 workers died related to falls from height. Over the last 5 years, falls from height mostly involved falls from a roof (13%), ladders (13%) and openings in floors, walls, or ceilings (8%).

What is the risk if i dont get my gear inspected?

Regular inspection of height safety equipment is essential for worker safety.

Equipment, including harnesses, lanyards, ropes, connectors, tie-off adaptors, and grabs, can be subjected to significant wear and tear, just from from everyday use.

Even minor defects, such as frayed ropes or worn-out harness stitching, can compromise the gear’s ability to withstand the huge forces generated during a fall.

This can place the user at risk of serious injury or death.

Inspections allow for the early detection of such issues, ensuring that any damaged equipment is either repaired or replaced promptly.

How often do i need to get my gear inspected?

A formal inspection by a qualified Height Safety Equipment Inspector, at specific intervals as defined in AS1891.4 2009, is not just a regulatory requirement, but a practical safety measure.

This regular assessment helps maintain the integrity of the equipment, ensuring it functions correctly in the event of a fall.

Height safety equipment that passes an inspection is not only safer but also extends the overall service life of the gear, providing cost savings by avoiding unexpected replacements due to neglect.

Can I inspect my own height safety gear?

All workers wearing or using height safety and fall arrest gear are required to give the equipment a pre- and post-use inspection.

AS1891.4 2009 outlines the requirement of having formal inspections conducted by qualified personnel at prescribed intervals. These Height Safety Equipmernt Inspectors have the experience and expertise to identify wear and tear that may not be visible to the untrained eye.

Inspections also ensure that equipment is being used and stored correctly. For example, improper storage of ropes and harnesses in areas exposed to extreme weather can accelerate material degradation.

The six-monthly inspection schedule serves as a checkpoint to guarantee that proper care is taken to preserve the functionality and safety of the gear.

Your safety & compliance

Maintaining your height safety equipment in accordance with regulatory standards not only keeps you compliant with site safety and regulatory requirements but also ensures that the gear remains in good working condition.

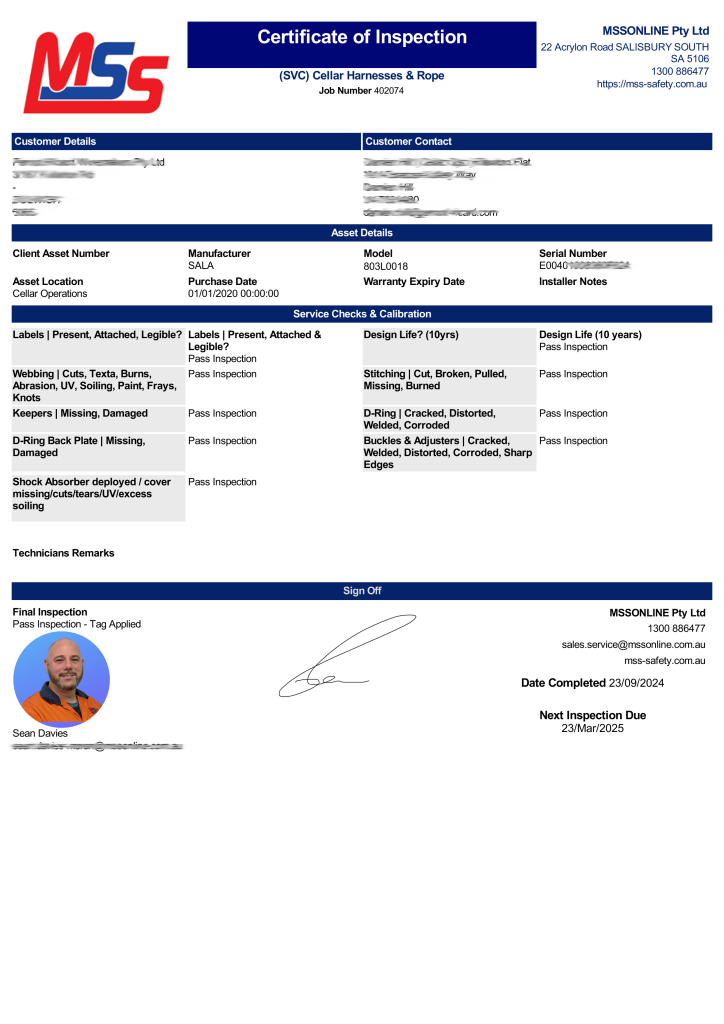

Detailed reports are required, not just tagging.

Regular inspections protect both the worker and the employer and will keep it functioning as intended, providing peace of mind that the gear will perform under critical conditions.

Where can i get my height safety gear inspected?

You bring your gear to us or we can come to you! We can even get it done while you wait (appointment required).

All equipment is inspected and recorded, added to your service database, with visual evidence into our Klipboard service management software.

Reports are available 24/7 through our portal, ensuring you can get evidence of inspection and certificates when you need them.

We will even send you a reminder by email and/or SMS in good time for your next inspection, ensuring no downtime.

How do i get my height safety inspection started?

Contact Us for a no obligation quotation.